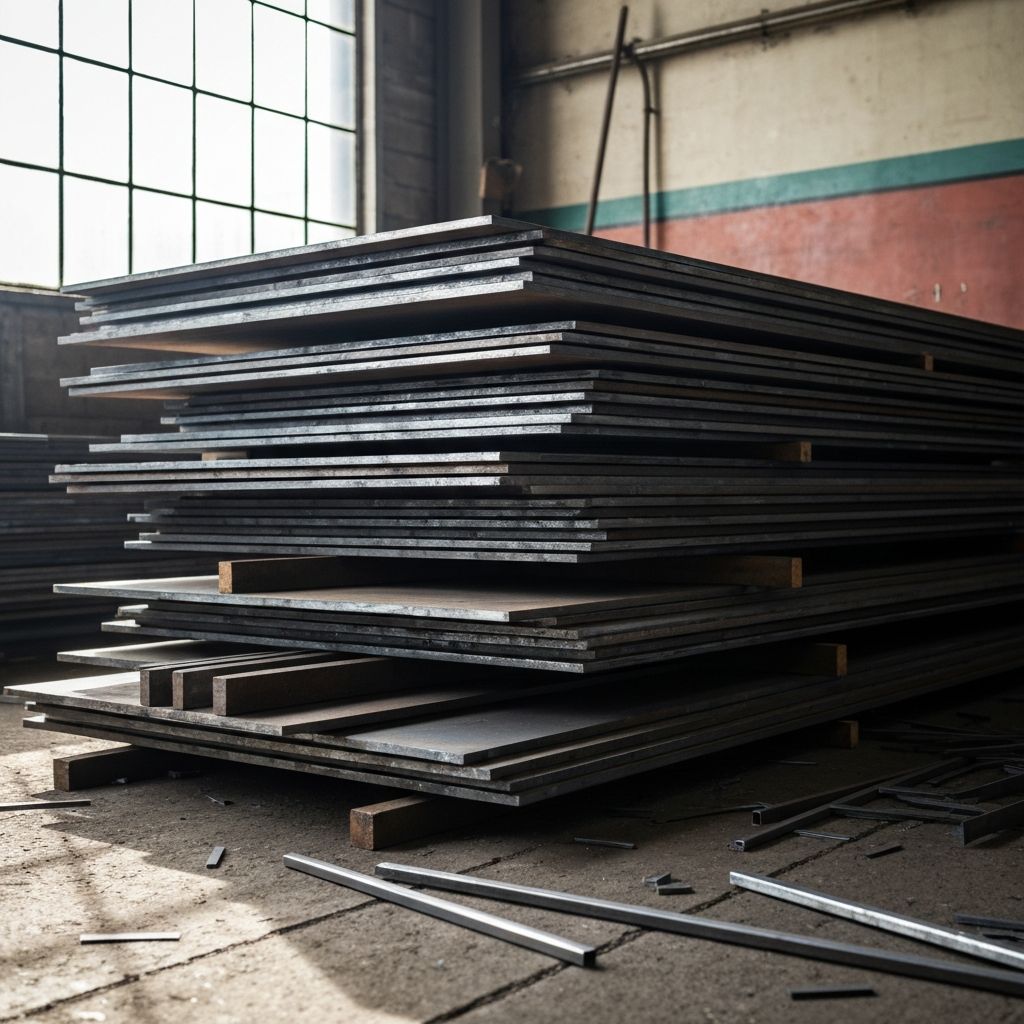

Steel Plates

Strong, versatile, and ready for heavy fabrication work

What Steel Plates Are Used For

Steel plates are the backbone of heavy fabrication work. They're used to build machinery bases, support frames, tanks, platforms, and large structural components that must hold serious weight. Because they're strong, durable, and dependable, metal shops rely on them for projects where stability and safety matter most.

Versatility in Fabrication

One of the biggest advantages of steel plates is how easily they can be formed into almost any shape. They can be cut, bent, welded, drilled, and machined without losing strength. This makes them ideal for custom fabrication, industrial equipment builds, and complex metal assemblies.

Multiple Grades & Thickness Options

Every project needs something different, so steel plates come in a wide range of grades and thicknesses. From thin sheets for lighter fabrication to heavy-duty plates used in structural engineering, you can match the exact specification required for load-bearing, pressure, or environmental conditions.

Reliable Strength for Industrial Projects

Steel plates are trusted across construction, manufacturing, transportation, and energy sectors because of their dependable strength. Whether it's a heavy machine base or a structural frame, the material delivers consistent performance under stress, impact, and long-term use.

Quality You Can Count On

Every steel plate goes through strict quality checks to ensure it arrives straight, smooth, and ready for fabrication. Consistent surface finish, uniform thickness, and accurate dimensions help shops avoid rework and keep production moving without delays.